Introduction – Emerging Trends Shaping the Aluminium Profile Industry

As industries embrace smart manufacturing, the demand for high-performance aluminium profiles is rapidly increasing. Industrial aluminium profiles are no longer just structural components—they are integral to automation, lightweight design, and sustainable production systems. With technological advancements in extrusion, coating, and precision engineering, companies like KaiMeiDa Aluminum are at the forefront of delivering innovative aluminium solutions for the factories of the future.

Lightweight and High-Strength Materials

Modern industrial projects require materials that are both lightweight and durable. Aluminium profiles provide an optimal balance:

Material Grades and Standards: KaiMeiDa offers a wide range of alloys, including 6063, 6060, 6005, 6061, 2014, 7005, and more, complying with GB/T6892-2008.

Strength-to-Weight Advantage: Lightweight profiles reduce machinery load and improve operational efficiency while maintaining structural integrity.

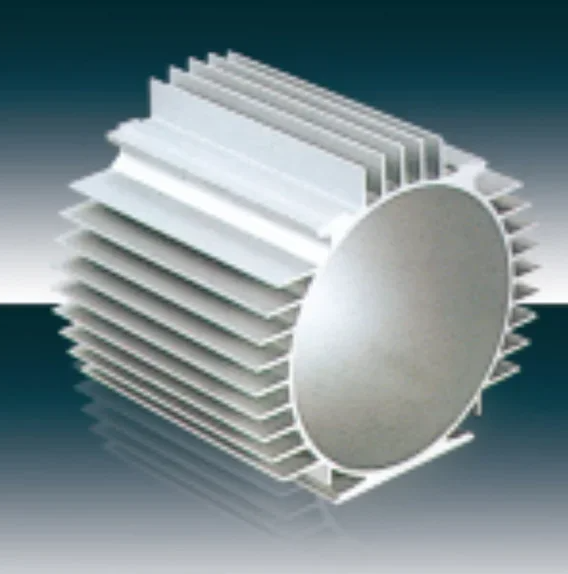

Maximum Extrusion Capacity: With extrusion presses up to 2500T, KaiMeiDa can produce high-strength industrial profiles suitable for heavy-duty applications.

These high-performance profiles allow manufacturers to build machinery frames, conveyor systems, and modular structures that are robust yet efficient.

Integration with Automation and IoT Systems

Smart manufacturing relies heavily on automation and data-driven systems. Industrial aluminium profiles are essential components in this ecosystem:

Machine Frames and Conveyor Structures: Custom profiles provide the foundation for precise, automated systems.

IoT Integration: Aluminium structures support sensors, monitoring devices, and robotic arms, facilitating real-time data collection.

Design Flexibility: Profiles can be tailored to meet specific automation layouts and operational requirements.

KaiMeiDa’s advanced extrusion and production capabilities ensure that aluminium profiles meet the exacting tolerances required for modern automated factories.

Sustainability and Eco-Friendly Profiles

Sustainability is a key trend in industrial manufacturing:

Recyclable Materials: Aluminium is fully recyclable without losing quality, aligning with green manufacturing initiatives.

Eco-Friendly Production: KaiMeiDa employs energy-efficient extrusion lines and environmentally responsible coating methods.

Compliance with Standards: Products meet national and international specifications, ensuring durability and reduced environmental impact.

Industrial aluminium profiles that combine energy efficiency, durability, and sustainability are critical for smart factories aiming for reduced carbon footprints.

Conclusion & Call to Action – KaiMeiDa: A Forward-Thinking Aluminium Profile Supplier

The future of industrial aluminium profiles lies in lightweight, high-strength, automation-ready, and eco-friendly solutions. KaiMeiDa Aluminum’s state-of-the-art production equipment, advanced coatings, and comprehensive alloy selection position it as a trusted partner for smart manufacturing initiatives

www.jxkmdly.com

Jiangxi Kaimeida Aluminum Co., Ltd.