In industries where precision mixing is essential, SS homogenizer tanks have become an indispensable part of the production line—especially when it comes to handling thick, viscous liquids. From food and beverage to pharmaceutical, cosmetic, and chemical processing, companies need equipment that can not only endure the demand of high-viscosity materials but also ensure consistency, hygiene, and efficiency. That's where Haishun Machinery shines.

Why Choose SS Homogenizer Tanks for Thick Liquids?

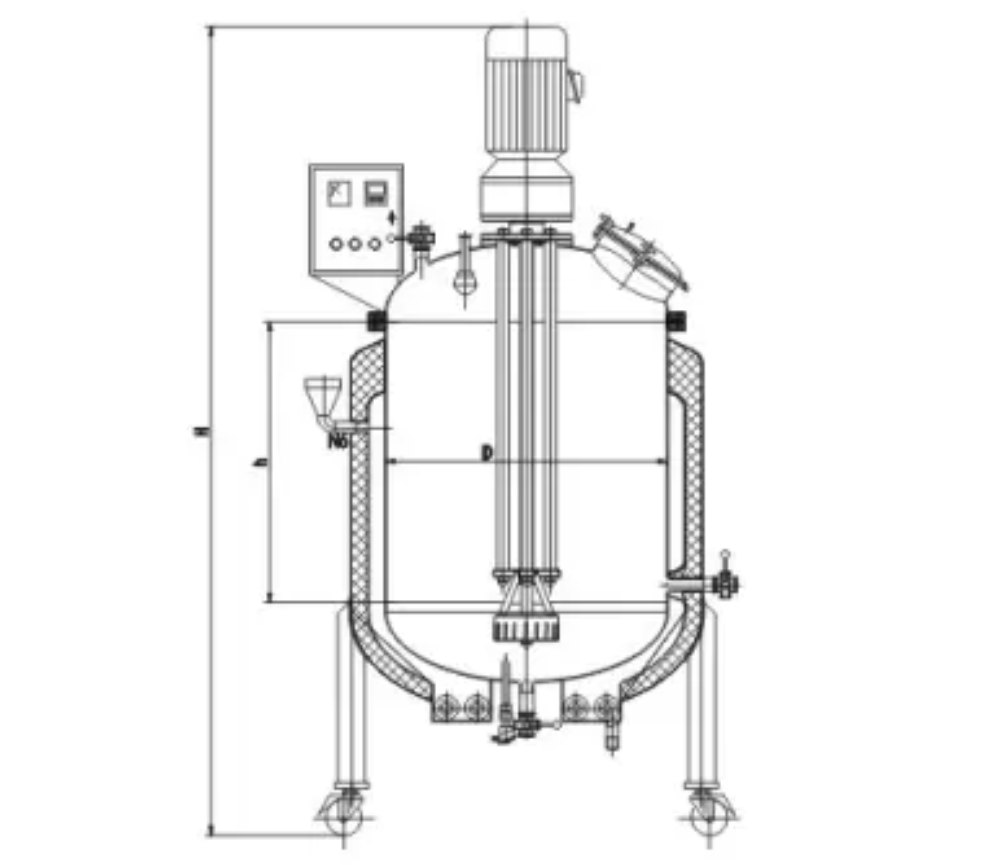

Unlike standard mixing tanks, homogenizer tanks are designed to deliver high-speed and high-efficiency mixing. When dealing with heavy, sticky, or gel-like materials, uniform mixing becomes a technical challenge. But with the homogenizer operating at 2000–3000 RPM, the tank can shear and disperse particles evenly throughout the solution—resulting in a smooth, lump-free product.

The centralized mixing design, whether at the top or bottom, allows for optimal blending of viscous materials. However, to ensure proper operation, the mixing axis must remain vertical—not tilted—so that the homogenizer can distribute the contents effectively and prevent uneven concentration zones within the tank.

Tailored Tank Structures for Every Process

At Haishun Machinery, customization is key. Their SS homogenizer tanks are available in SS304, SS316, and SS321 stainless steel grades to meet the varying needs of industry-specific standards and corrosion resistance requirements.

You can choose from the following tank configurations:

Single Layer:

Includes only the tank body. Suitable for non-temperature-sensitive applications.Double Layer:

Tank body with either:Cooling/heating jacket – for temperature control of the material.

Insulation layer – to prevent heat loss or maintain internal temperature.

Three Layer:

A complete structure of tank body + jacket + insulation, ideal for complex and temperature-sensitive processes in cosmetics, pharmaceuticals, and specialty chemicals.

Precision Meets Durability

Each tank is engineered with reliable high-speed homogenization technology and fabricated with a hygienic design that supports CIP/SIP cleaning. The homogenizer can also be combined with other types of mixers, offering versatility for multi-phase materials or dual-process requirements.

With years of manufacturing excellence, Haishun Machinery guarantees:

Consistent product quality across batches

Stable performance even during extended operation

Reduced energy usage with efficient mixing systems

Custom sizing to fit your plant layout and production volume

Applications in Viscous Liquid Industries

SS Homogenizer Tanks are ideal for:

Mayonnaise, ketchup, sauces

Pharmaceutical syrups and creams

Cosmetic lotions, pastes, and gels

Chemical emulsions and adhesives

Paints, resins, and pigment dispersions

No matter how thick or dense your material is, Haishun’s homogenizer tanks can handle it with unmatched consistency and control.

Why Haishun Machinery?

Haishun Machinery is a trusted name in stainless steel mixing technology, with a strong reputation for producing high-quality tanks, fermenters, and brewing equipment. With complete customization options, advanced technical solutions, and professional after-sales service, Haishun has become a reliable partner in the pharmaceutical, food & beverage, and chemical industries worldwide.

Looking to improve your mixing process for viscous liquids?

Contact Haishun Machinery today to explore your custom SS homogenizer tank solution tailored to your application needs.

https://www.haishunmachinery.com/

HANGZHOU HAISHUN MACHINERY Co., Ltd