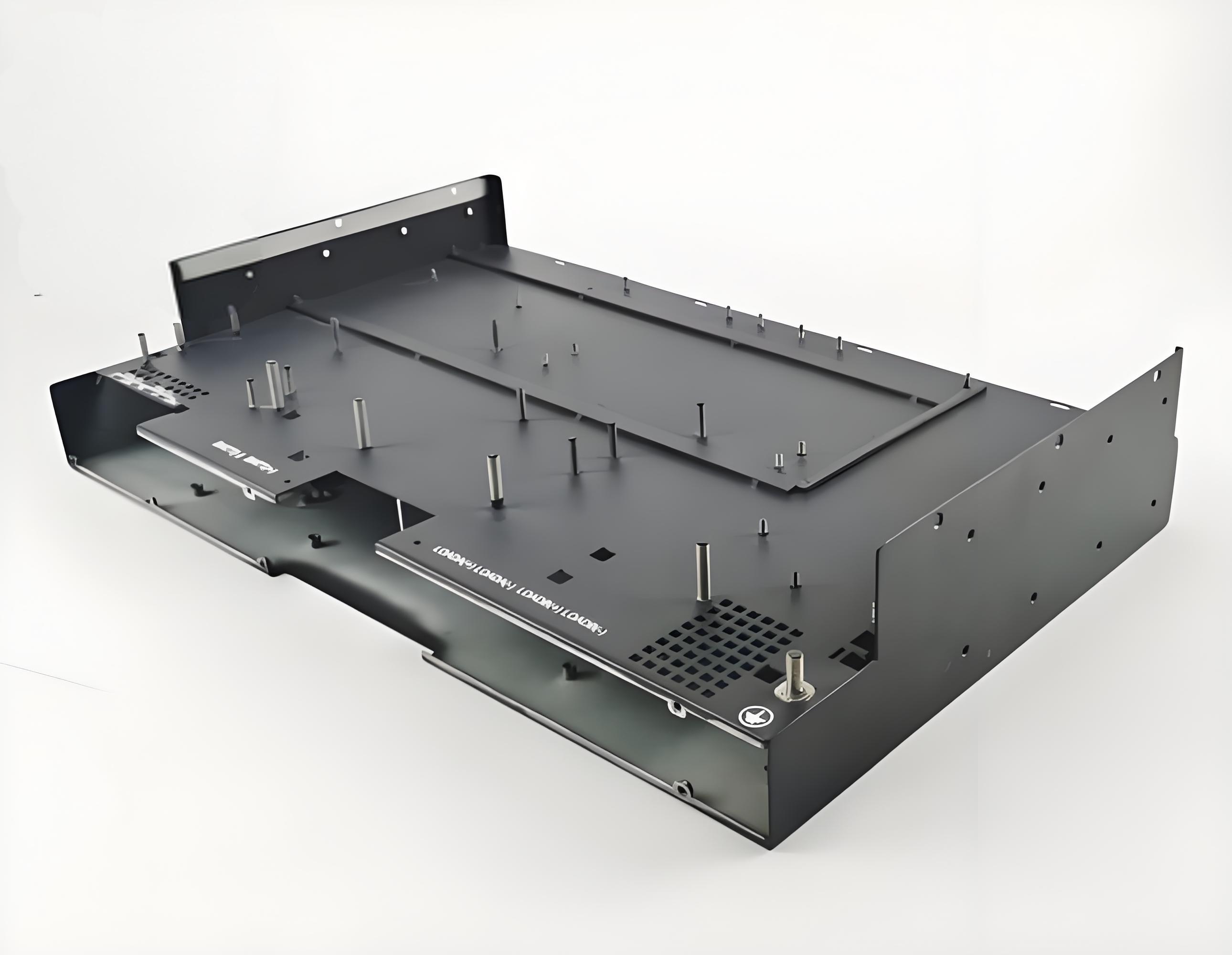

Sheet metal fabrication enclosures play a critical role in modern industries—from protecting sensitive electronics to housing mechanical components in automation systems. As demand for high-performance, custom-engineered enclosures grows, understanding the materials, types, and applications becomes essential for product designers, engineers, and OEMs.

In this guide, we’ll explore everything you need to know about sheet metal fabrication enclosures, and how an expert manufacturer like Linkwork Precision Machinery can provide tailored solutions for your most demanding projects.

What Is a Sheet Metal Fabrication Enclosure?

A sheet metal fabrication enclosure is a protective casing made by cutting, bending, and assembling metal sheets into a final structure. These enclosures are designed to:

Shield internal components from dust, moisture, and electromagnetic interference

Provide structural integrity for electrical or mechanical systems

Support ventilation and thermal management

Offer a clean, customizable form factor for branding or user interfaces

They are widely used in industries such as electronics, telecommunications, automotive, aerospace, medical equipment, and more.

Common Materials Used in Sheet Metal Enclosures

Choosing the right material is key to achieving the desired durability, corrosion resistance, weight, and cost. Here are the most popular materials:

1. Stainless Steel

Excellent corrosion resistance

Ideal for medical, food-grade, or outdoor enclosures

High strength and premium appearance

2. Aluminum

Lightweight and corrosion-resistant

Good thermal and electrical conductivity

Suitable for aerospace and portable electronic devices

3. Carbon Steel

Cost-effective and easy to machine or weld

Can be powder-coated or painted for protection

Common in industrial and automation enclosures

4. Copper and Brass

Excellent conductivity

Mostly used for EMI shielding and specialty electronic housings

Linkwork Precision Machinery provides a full range of material options and supports material certification, surface treatment (such as anodizing, painting, or plating), and precision tolerances tailored to your specific application.

Types of Sheet Metal Fabrication Enclosures

The type of enclosure depends on the form factor and functional requirements of the product. Common types include:

1. Rackmount Enclosures

Used in servers, telecom, and AV equipment

Standardized sizes (1U, 2U, etc.) with customizable front panels

2. Console and Desktop Enclosures

Designed for control systems or user interfaces

Often include cutouts for buttons, screens, or ports

3. Wall-Mounted Boxes

Ideal for electrical distribution or monitoring systems

Provide easy access while saving floor space

4. Portable Enclosures

Compact and lightweight, often used for instruments or handheld devices

Typically require high precision and aesthetic finishes

At Linkwork, we offer custom-built enclosures using CNC milling, turning, and sheet metal fabrication—all under one roof. From a simple box to a complex multi-component housing, we bring designs to life with unmatched precision.

Key Applications Across Industries

Sheet metal enclosures are found in nearly every industry. Here are just a few of the many applications:

Electronics: PCB housing, EMI shielding boxes

Automotive & Motorcycle: Control unit covers, battery enclosures

Medical Devices: Diagnostic machine casings, sterilizable housings

Aerospace: Lightweight instrument panels and enclosures

Industrial Automation: Sensor housings, PLC cabinets

Renewable Energy: Inverter enclosures, battery management units

Linkwork Precision Machinery proudly serves these industries with custom CNC-machined parts and sheet metal assemblies, combining fast prototyping with scalable mass production capabilities.

Why Choose Linkwork Precision Machinery?

As a trusted manufacturer of precision mechanical parts and sheet metal components, Linkwork Precision Machinery offers:

Advanced CNC turning, milling, and sheet metal fabrication technologies

Flexible production, from prototypes to large-scale batches

Expertise in mechanical, electronic, medical, aerospace, and energy sectors

Strict quality control and international standards compliance

Custom design support to optimize performance, function, and aesthetics

Our team collaborates closely with clients to deliver durable, functional, and cost-effective enclosures—on time, every time.

Final Thoughts

When it comes to creating robust, functional, and visually appealing enclosures, sheet metal fabrication remains a reliable and versatile method. Whether you're building industrial machines or launching a high-tech consumer product, the right enclosure can make a difference in performance and longevity.

Partner with Linkwork Precision Machinery to get high-precision, custom-fabricated enclosures that match your specifications and exceed your expectations.

www.szlinkwork.com

Shenzhen Linkwork Precision Machinery Co., Ltd.