In the world of modern engineering, precision gear manufacturing plays a vital role in ensuring the smooth and reliable operation of countless mechanical systems — from automotive transmissions and industrial gearboxes to motorcycles, pumps, and synchronizing pulleys. At the heart of this process lies the gear hobbing machine, a cornerstone of high-accuracy, high-efficiency gear production.

What Is a Gear Hobbing Machine?

A gear hobbing machine is a specialized piece of equipment designed to cut gears, splines, and sprockets through a continuous generating process known as hobbing. The machine uses a rotating cutting tool (hob) that works in synchronized motion with the workpiece to gradually shape the gear teeth. Compared with other gear-cutting methods, hobbing is renowned for its speed, precision, and versatility, making it a preferred choice for mass production and precision machining.

1. Exceptional Accuracy and Surface Finish

One of the key benefits of using a gear hobbing machine is its superior precision. Modern CNC-controlled hobbing machines can achieve micron-level accuracy, ensuring each gear tooth is formed with perfect geometry. This high level of precision is crucial for applications in automotive and aerospace industries, where gear performance directly impacts power transmission efficiency and overall system stability.

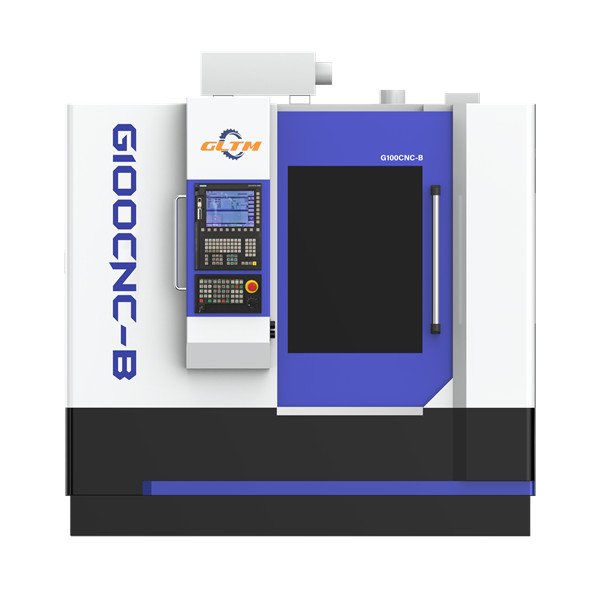

Companies like GLT Machinery (GLTM/GLT) have set industry benchmarks with their high-speed, high-efficiency CNC gear hobbing machines. Designed with high rigidity, stability, and accuracy, GLT’s machines guarantee smooth operation and consistent precision across large production runs.

2. High Efficiency for Mass Production

Efficiency is a top priority in modern gear manufacturing. Gear hobbing machines are capable of producing multiple gears in a fraction of the time required by other machining methods. The continuous hobbing process minimizes downtime and allows for high throughput, making it ideal for automotive gear production, motorbike transmissions, and industrial machinery.

GLT Machinery’s CNC hobbing machines are optimized for high-speed cutting and automated production, significantly improving productivity while maintaining precision. This balance of speed and quality helps manufacturers reduce production costs and meet tight delivery schedules.

3. Versatility Across Gear Types and Materials

Another major advantage of gear hobbing machines is their ability to handle a wide range of gear sizes, modules, and materials — from steel and aluminum to specialized alloys. Whether it’s spur gears, helical gears, or worm wheels, hobbing machines can adapt to different designs with minimal reconfiguration.

GLT’s machines are widely applied across various sectors, including automobiles, motorcycles, reducers, synchronous pulleys, and pump manufacturing. This flexibility allows customers to produce multiple gear types on the same equipment, reducing investment and improving operational versatility.

4. Enhanced Tool Life and Reduced Maintenance

Advanced gear hobbing machines are engineered for durability and low maintenance. With features such as automatic lubrication systems, vibration control, and temperature compensation, these machines deliver stable performance over long production cycles.

GLT Machinery incorporates robust mechanical structures and intelligent digital control systems into their CNC hobbing machines to ensure extended tool life and minimal machine wear, helping users reduce downtime and maintenance costs.

5. Seamless Integration with Digital Manufacturing

As manufacturing moves toward Industry 4.0, CNC gear hobbing machines have evolved to support digital monitoring, intelligent programming, and data-driven production. With integration capabilities for CAD/CAM systems, operators can easily program and monitor gear production processes with real-time feedback and precision adjustments.

GLT’s advanced CNC systems allow for seamless communication between machines and production lines, helping manufacturers achieve automated, smart, and efficient gear production environments.

Conclusion

The adoption of gear hobbing machines has transformed the way industries approach precision gear manufacturing. With outstanding advantages in accuracy, efficiency, flexibility, and durability, these machines are indispensable tools for companies seeking to improve productivity and quality.

As a trusted manufacturer, GLT Machinery (GLTM/GLT) continues to deliver world-class CNC gear hobbing solutions backed by innovative technology and proven reliability. Whether in automotive, motorcycle, or industrial gear applications, GLT’s machines empower customers to achieve higher efficiency, superior precision, and long-term success in the competitive gear manufacturing landscape.

www.gltmachinery.com

Wuxi General Machinery Co., Ltd. (GLTM / GLT)