Introduction

In the world of precision engineering and mechanical design, springs are the hidden workhorses. They absorb energy, balance forces, and ensure the reliability of countless machines and systems. Among the wide variety of spring technologies, disc springs—also known as Belleville washers—stand out for their unique combination of compact design and extraordinary performance. When compared with traditional compression springs, high-performance disc springs not only maximize load capacity but also extend service life, making them a preferred choice in demanding applications.

As a reliable disc spring manufacturer, RALEIGH SPRING has been at the forefront of designing and supplying customized solutions to industries worldwide. Backed by DIN 2093 standards and advanced production expertise, Raleigh delivers products that meet the highest quality requirements while offering flexibility for engineers and designers.

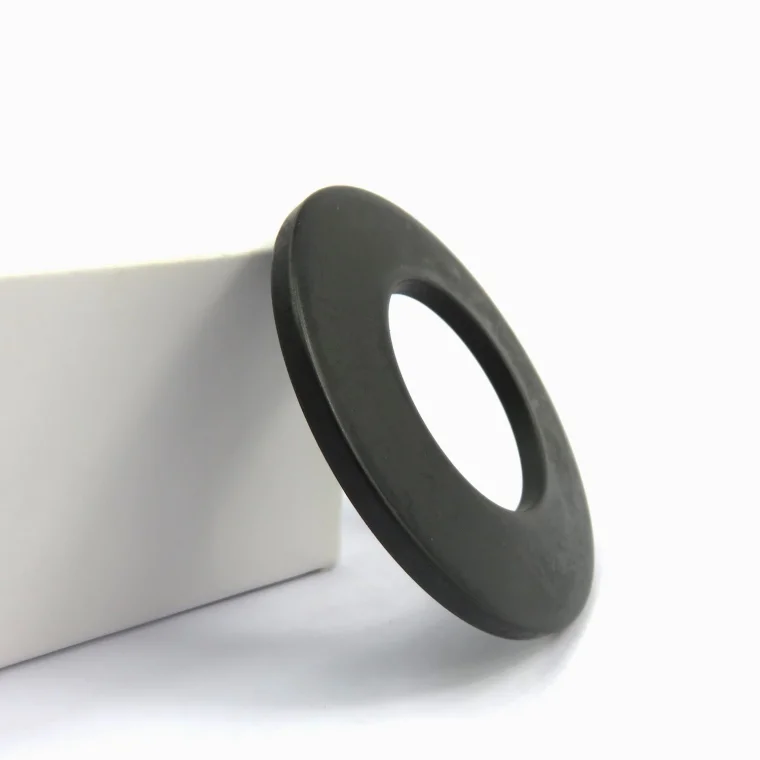

What Are Disc Springs?

Disc springs are annular coned elements that resist axial compressive loads. Unlike helical compression springs, disc springs deliver high force within a compact design, making them ideal for applications where space and weight are critical.

Single disc springs: Provide straightforward load absorption.

Stacked disc springs: Multiple discs can be arranged in parallel, series, or a combination, allowing engineers to achieve tailored force-deflection curves.

Static and fatigue loading: Disc springs are capable of withstanding both constant and cyclic loads, ensuring reliability in long-term service.

Flat bearings: Often paired with disc springs to enhance performance and minimize wear.

Why High-Performance Disc Springs Excel

Compared to traditional compression springs, disc springs offer unique advantages:

Compact Size, Higher Force Output

A single disc spring can deliver far greater force than a helical spring of comparable size. This compact design saves valuable space in machinery without compromising strength.Load Flexibility Through Stacking

Engineers can fine-tune performance by stacking discs in parallel to increase force, or in series to increase deflection. This versatility is unmatched by traditional compression springs.Resistance to Fatigue

Designed to withstand repetitive cycles, disc springs maintain their performance even under fatigue loading. This ensures longer service life, reducing maintenance downtime.Better Stress Distribution

High-performance disc springs distribute stresses more efficiently, minimizing the risk of deformation and premature failure.Suitability for Extreme Environments

Disc springs are designed to perform in high-temperature, corrosive, and high-vibration environments where conventional springs might fail.

Applications Across Industries

High-performance disc springs are indispensable in industries where reliability and durability are critical:

Aerospace & Defense: For shock absorption, vibration damping, and load regulation in aircraft systems.

Automotive & Motorsport: Clutches, braking systems, and suspensions rely on disc springs for high-performance operation.

Energy & Power Generation: Turbines, wind power systems, and nuclear plants use disc springs to maintain stability under extreme stress.

Oil & Gas: Used in drilling and extraction equipment where high loads and harsh environments are the norm.

Industrial Machinery: Compressors, valves, and gear systems benefit from the compact yet powerful load-bearing capacity of disc springs.

Raleigh Spring: DIN 2093 Disc Spring Expertise

At RALEIGH SPRING, we manufacture disc springs that conform to DIN 2093 standards, ensuring precise dimensions, consistent performance, and reliable quality.

DIN2093 Metric Disc Washer Series: Designed to meet diverse applications across industries.

Customized Solutions: Raleigh expands upon standard DIN sizes, offering tailored designs for unique requirements.

High-Quality Materials: Manufactured from premium alloys to enhance fatigue strength, corrosion resistance, and high-temperature stability.

Strict Quality Standards: Every product adheres to DIN manufacturing and quality specifications, ensuring consistency and dependability.

Engineering Support: Raleigh’s team provides guidance to product designers seeking flexible, application-specific solutions.

Comparing Disc Springs with Compression Springs

| Feature | High-Performance Disc Springs | Traditional Compression Springs |

|---|---|---|

| Load Capacity | High force in compact size | Lower force for comparable size |

| Space Efficiency | Requires less space | Requires more space |

| Customization | Easily stackable for tailored performance | Limited flexibility |

| Fatigue Resistance | Superior under cyclic loading | Moderate, may degrade faster |

| Durability in Harsh Environments | Excellent performance | Susceptible to failure |

| Service Life | Extended lifespan | Shorter lifespan |

This comparison makes it clear why industries demanding both strength and reliability increasingly turn to disc springs.

Real-World Performance Benefits

Extended Equipment Lifespan: By reducing wear and fatigue, disc springs contribute to longer operational life for critical systems.

Cost Efficiency: Although initial investment may be higher, the reduced need for replacement and downtime results in long-term savings.

Safety Assurance: Disc springs maintain stability even under fluctuating or extreme conditions, ensuring safe and consistent operation.

Design Flexibility: Raleigh’s ability to customize sizes and configurations allows engineers to achieve precise performance goals.

Customized Manufacturing by Raleigh Spring

One of Raleigh’s greatest strengths lies in its custom manufacturing services. Whether you need disc springs for aerospace-grade durability, automotive clutch assemblies, or heavy industrial equipment, Raleigh can deliver:

Custom Sizes: Expanded options beyond DIN 2093 tables.

Surface Treatments: To enhance corrosion resistance and fatigue life.

Special Materials: Stainless steel, Inconel, or other alloys for extreme environments.

Precision Machining: Tight tolerances ensure consistency and reliability.

Conclusion

When it comes to maximizing load and extending service life, high-performance disc springs are in a league of their own compared to traditional compression springs. Their compact design, stacking flexibility, and fatigue resistance make them essential in modern engineering solutions.

With RALEIGH SPRING as your trusted partner, you can count on precision-manufactured disc springs that meet DIN 2093 standards and beyond. Whether for aerospace, automotive, energy, or industrial applications, Raleigh delivers products that combine innovation, reliability, and long-term value.

For designers and engineers seeking a reliable disc spring manufacturer, Raleigh provides not just components, but complete performance solutions.

www.raleigh-springs.com

RALEIGH SPRING