In recent years, 3D printing has emerged as a groundbreaking technology with the potential to revolutionize various industries. This additive manufacturing process allows for the creation of three-dimensional objects from digital designs, opening up a world of possibilities. In this article, we will delve into the three types of 3D printing that are driving innovation and transforming the way we manufacture and create.

- Fused Deposition Modeling (FDM):

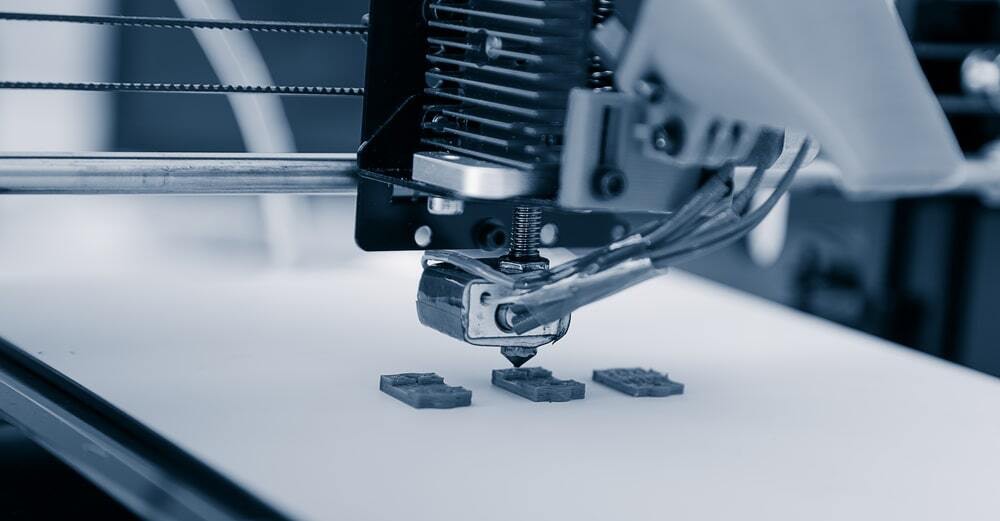

Fused Deposition Modeling, also known as FDM, is one of the most widely used 3D printing techniques. It involves the extrusion of a thermoplastic filament through a heated nozzle, which deposits layer upon layer to build the final object. FDM offers versatility and affordability, making it popular among hobbyists, educators, and small businesses. Its applications range from rapid prototyping and product development to custom manufacturing and even medical device production. - Stereolithography (SLA):

Stereolithography, or SLA, is a type of 3D printing that utilizes photopolymerization to create objects. It works by using a laser to selectively solidify liquid resin, layer by layer, to form the desired shape. SLA is known for its high precision and smooth surface finish, making it ideal for creating intricate and detailed models. This technology finds applications in industries such as jewelry, dentistry, and automotive, where precision and aesthetics are crucial. - Selective Laser Sintering (SLS):

Selective Laser Sintering, or SLS, is a 3D printing technique that employs a high-powered laser to fuse powdered materials together. Unlike FDM and SLA, SLS does not require support structures, as the unsintered powder acts as a self-supporting medium during the printing process. This makes SLS suitable for producing complex geometries and functional parts. Industries such as aerospace, automotive, and healthcare benefit from SLS due to its ability to create durable, high-performance components.

Conclusion:

The world of 3D printing is rapidly evolving, and these three types of 3D printing—FDM, SLA, and SLS—are at the forefront of this technological revolution. Each technique offers unique advantages and applications, catering to different industries and manufacturing needs. As the technology continues to advance, we can expect further innovations and improvements in 3D printing, opening up new possibilities for design, production, and customization.