In industries such as industrial manufacturing, petrochemicals, and construction engineering, orbital pipe cutting machines are widely used in cutting operations of various types of pipes due to their high efficiency, precision, and convenience. With the widespread popularity of equipment, how to correctly perform daily maintenance and effectively extend the service life of the equipment has become the focus of many companies. This article will systematically sort out the maintenance of orbital pipe cutting machines to help users master scientific maintenance skills and achieve efficient management and use of equipment.

1. Introduction to orbital pipe cutting machines

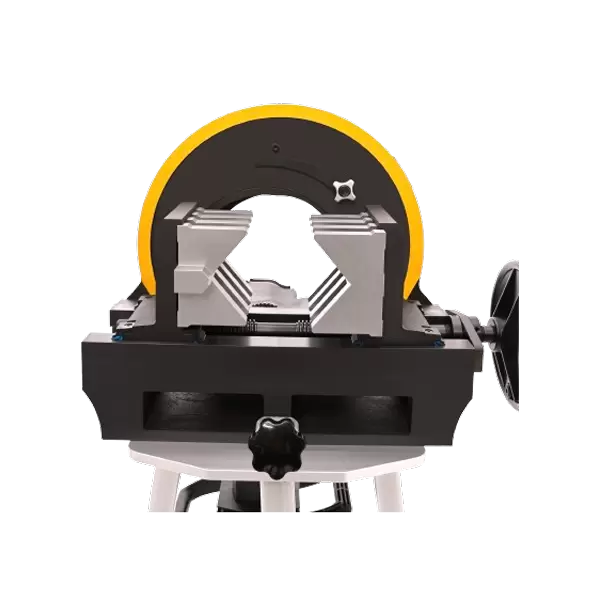

The orbital pipe cutting machine is an automated equipment designed for pipe cutting. It is mainly composed of a track system, a cutting device, a drive mechanism, an electrical control system, and auxiliary accessories. The equipment achieves high-precision cutting along the surface of the pipe by installing a track on the outside of the pipe. It is suitable for pipes of various materials such as carbon steel, stainless steel, and alloy steel.

2. Why is daily maintenance so important?

Due to the complex operating environment and long continuous operation time, the orbital pipe cutting machine is easily affected by dust, oil, high temperature, high pressure, and other factors during use. If it is not maintained in time, it is easy to cause problems such as increased wear of mechanical parts, frequent electrical failures, and decreased cutting accuracy. Long-term neglect of maintenance not only affects production efficiency, but may also lead to equipment scrapping and increase enterprise operation and maintenance costs. Therefore, establishing a scientific and standardized daily maintenance mechanism plays an important role in extending the life of the equipment.

3. Maintenance points of orbital pipe cutting machine

Cleaning and maintenance

Cleaning immediately after operation: After each operation, clean the iron filings, cutting residues, oil stains, etc. on the surface of the machine in time to prevent corrosion.

Guide rail cleaning: Use non-woven cloth or soft brush to clean the surface of the guide rail regularly to avoid dust and iron filings from accumulating and affecting the running accuracy.

Mainframe housing wiping: Use slightly damp cloth to wipe the housing, and do not rinse directly with water to prevent water damage to the electronic control system.

Lubrication and maintenance

Guide rail lubrication: According to the frequency of use, add special lubricating oil for the guide rail at least once a week to ensure smooth movement.

Gear/chain lubrication: Check the lubrication status of the gear or chain regularly, add or replace the grease, and prevent aggravated wear due to dry grinding.

Slider lubrication: The slider is a key structure that carries the moving parts and needs to be kept well lubricated. It is recommended to add grease every 100 hours of operation.

Tightening inspection

Bolts and nuts: Check whether the bolts and nuts of all connection parts are tight, especially the connection between the track and the main machine and the clamping device.

Cable plug: Check whether the cable interface is firm and not loose to prevent power failure or short circuit due to poor contact during cutting.

Electrical system inspection

Electric control box: Open the electric control box regularly to check for problems such as line aging, loose wiring, and component damage.

Buttons and touch panels: Test whether the emergency stop button, start button, direction keys, etc. are sensitive and reliable.

Motor status: Observe whether the sound of the motor is normal, check whether the temperature is too high, and measure the current value if necessary.

Cutting system maintenance

Nozzle/cutting nozzle: Flame or plasma cutting systems need to regularly check whether the cutting nozzle is blocked or deformed to keep the air flow unobstructed.

Gas system: Check whether the air pipe is leaking, aging or bending, and clean the filter element to ensure stable air pressure.

Electrode and spray cap (plasma cutting): Replace severely worn electrodes or spray caps in time to ensure cutting stability and efficiency.

4. Tips to improve maintenance efficiency

Establish a maintenance system: clarify the person in charge, time nodes, and inspection standards;

Develop inspection forms: daily inspection by operators + regular inspection by maintenance workers;

Use label management: label the inspected parts for easy tracking;

Train operators: popularize knowledge of daily equipment inspection;

Configure a special tool box: avoid using inappropriate tools to cause equipment damage.

5. Precautions (avoid accelerated aging)

Avoid overload operation: When cutting, choose a reasonable speed and gas pressure according to the pipe material to avoid equipment overload.

Avoid frequent start and stop: Continuous start and stop will increase the wear of the motor and gears. It is recommended to arrange the operation process reasonably.

Avoid high temperature and high humidity environment: Humidity and high temperature can easily cause short circuit or rust of the electronic control system. It is recommended to configure drying equipment or ventilation devices.

Prevent impact and fall: Shockproof packaging should be done during transportation or handling to avoid damage to precision parts such as tracks and main machines.

Fixed person and fixed post management: Operators should be professionally trained to avoid equipment damage caused by misoperation.

As a high-precision and high-efficiency industrial equipment, the life of the orbital pipe cutting machine depends not only on the manufacturing quality, but also on the careful maintenance and scientific management of the user. Through scientific maintenance plans, professional operators and standardized use processes, not only can the service life of the equipment be significantly extended, but also the cutting accuracy and work efficiency can be improved, so as to truly achieve the goal of "maintenance instead of repair, reducing costs and increasing efficiency".

As a professional orbital pipe cutting machine factory, we are not only committed to providing customers with high-performance and high-precision cutting equipment, but also attach more importance to after-sales service and usage guidance. In the product design stage, we fully consider the stability and maintainability of the equipment in long-term operation, and provide detailed maintenance manuals and operation training support to help customers reduce the failure rate and extend the service life of the equipment. We firmly believe that only when the equipment is stable and reliable and properly maintained can the customer's investment value be maximized.

https://www.nodha.com/blog/Daily-maintenance-guide-for-orbital-pipe-cutting-machines-to-extend-the-s

NODHA Industrial Technology Wuxi Co., LTD